Vibration Analysis

James Electric Motor Services Ltd. offers one-time or continued/periodic monitoring for fan motors, pump motors, and pumps for every application. We consider this analysis an essential service for critical equipment, as it improves and maintains reliability, safety and production.

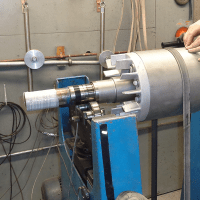

A qualified James Electric Service Technician will perform a complete analysis on your motor or pump which includes the following:

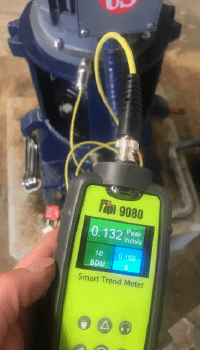

Obtain Data

- Shaft vibration

- Housing vibration

- Time-waveform analysis

- Phase analysis

- Synchronous vibration peaks

- Asynchronous vibration peaks

- Sub-synchronous peaks

- Critical machine speeds

Inspect

Motor, coupling, rotational elements, belts and hardware for:

- Unusual and expected damage/wear Looseness

- Misalignment

- Lubrication

- Imbalance

- Terminal motor connections

Identify

Using data obtained from our analysis we will identify the causes for repair, replacement, or adjustment of the machine.

- Structural resonance

- Hot and cold alignment

- Shaft integrity

- Machine critical speeds

- Gear, blade, and vane disturbances

- Recirculation & cavitation

- Motor faults (rotor & stator)

- Bearing failures

- Mechanical looseness

- Recurring problems and inconsistent operation

Upon completion of the tests we will provide a written report of the operation and condition of your motors or pumps. If desired we will provide a written quotation of any required repairs.

Call for pricing

Pricing is subject to change based on work required

Please Note: If we determine that the fan motor, pump motor or pump is no longer operational, we can complete the required repairs immediately at the customers discretion. We advise this be done to maintain safety standards.