Pump System Preventative Maintenance Inspection

James Electric Motor Services Ltd. offers a one-time or continued/periodic monitoring for pumps and pump motors for every application. We consider this analysis an essential service for critical equipment, as it improves and maintains reliability, safety and production.

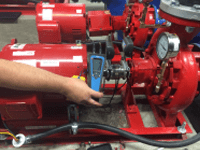

In the course of this inspection, James Electric will:

- Inspect all electrical connections in the Motor Starter/Control Panel. Tighten as required.

- Inspect all contactors, relays, switches for correct operation.

- Inspect the electrical terminations in the motor junction box. Tighten as required.

- Verify voltage and operating current

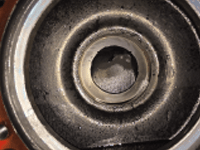

- Perform audible check of motor bearings for wear.

- Check pump seals for active leaks.

- Perform audible check of pump bearings, if applicable, for wear.

- Check pump to motor shaft and coupling for wear and correct alignment, if applicable.

- Verify correct operation of pressure gauges.

- Note all observations on the inspection report.

In addition to the aforementioned preventative maintenance inspection service, James Electric also offers instantaneous and trending vibration analysis of motor and fan bearings. Instantaneous analysis will indicate bearings that are in an imminent failure state whereas trending analysis will indicate wear over time. The vibration analysis service can be offered both separately and independently of the pump preventative maintenance service. If you are interested in learning more about the vibration analysis option, please discuss it with your salesperson.

Upon completion of the inspection, we will provide:

- A written report of our findings and any recommendations

- A written quotation for any recommended repairs that were not immediately authorized and completed during the inspection.

Call for pricing

Pricing is subject to change based on work required

Please Note: If we determine that the pump or pump motor is no longer operational, we can complete the required repairs immediately at the customers discretion. We advise this be done to maintain safety standards.