Heat Exchanger Servicing & Repair

Why Service?

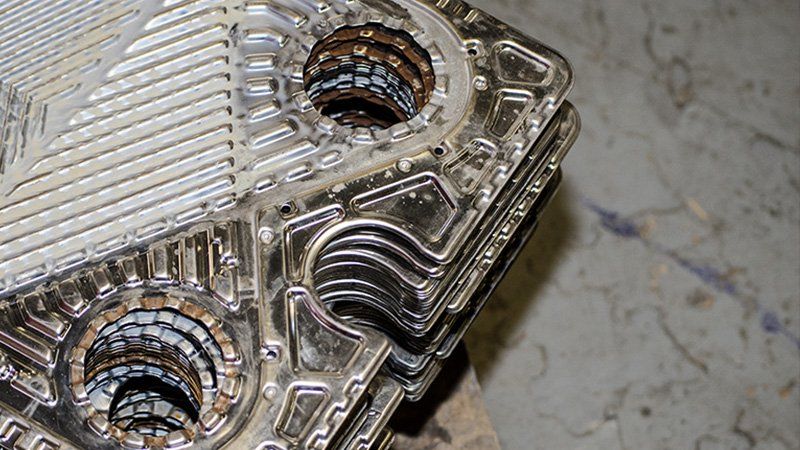

Heat exchangers have no moving mechanical parts and so often get ignored until they fail. Plate and frame heat exchangers utilize a tremendous surface area to allow an efficient exchange of heat in a relatively small space. This large surface area is achieved by the use of specially corrugated metal plates (media plates) sealed with gaskets and compressed to a set dimension. The temperature is then transferred between two separate fluid systems by pumping hot through one side of a plate and cold through the other. These small pathways make for an extremely efficient transfer of heat, however, they can also act like a filter creating a congestion point for any debris in your system. This problem exists for both new and older buildings, as during construction they often get plugged with welding slag, etc. which seriously reduces the heat exchangers ability to transfer heat effectively.

What We Do

We can isolate and drain both sides of your heat exchanger and use our custom built 50 tonne hydraulic rams to safely decompress the plates. We then mark and remove each plate and individually clean both sides. Each plate is inspected for any obvious defects and if need be they can be run through a leak detection process.

All damaged gaskets are then replaced and the plates are reinstalled in the same order they were removed. Our hydraulic rams are then used to recompress your heat exchanger back to factory specifications and dimensions.

With all of our reports, a file is generated which contains the following pertinent information:

- Photos

- Nameplate information

- Flow information and parameters

- Previous work reports

If future service is required, simply call us and we will pull your file prior to going to site. This will ensure that we are aware of what equipment and parts may be required which can help reduce the downtime of your system.